HOW TO

Getting Started

Seeing them fly is amazing, but ornithopters are not easy to build. You can improve your chances of success if you start off with a proven design, before beginning your own experiments.

There are a few things you should watch out for. Beware of any instructions for building your own ornithopter from household materials. Using the right materials is important to building a successful ornithopter. Also avoid cheap ornithopter kits that have a lot of plastic or bamboo parts. I worry that some people try these models and then conclude that they can't build an ornithopter that works.

Fortunately, there are some simple ornithopter designs that actually fly. Start with a proven design, the Ornithopter Society's Freebird Plans. The experience of building one of these rubber-band-powered ornithopters will teach you basic concepts and help ensure the success of your future endeavors.

The information on this page is from the Ornithopter Design Manual by Nathan Chronister. You can download the Ornithopter Design Manual here.

Electric Power

After you build a few rubber-band-powered ornithopters, you might want to try an electric powered ornithopter. There are several types of electric motor that may be used in an ornithopter. The selection of motor type will depend on your specific project.

The standard brushed motor is the oldest type and the most familiar to most people. These motors have a central, rotating shaft called the "armature". The armature has coils of wire, which are electromagnets. They push against permanent magnets in the motor casing to make the motor turn. Electrically conductive "brushes" transfer power to the rotating shaft. As the motor turns, these brushes are designed to switch the electromagnets on and off in a specific sequence, which allows continuous rotation. Brushed motors are the least expensive type, and a properly selected brushed motor will supply enough power for ornithopter needs.

In a "brushless" type motor, the electromagnets are switched on and off electronically, instead of using the mechanical contacts or brushes. This is more efficient, but it requires a special electronic device called a brushless motor controller. Brushless motors have permanent magnets on the armature, and they have electomagnets in the stationary part of the motor. Brushless motors have three wires instead of two.

There are two types of brushless motors, called "outrunners" and "inrunners". The inrunner has electromagnets in a stationary outer case. The inside part of the motor rotates. However, in the outrunner, the outer case of the motor rotates. The electromagnets are on the inside, and that part is stationary. Outrunners generally have a lower RPM and more torque. For that reason, they don't need as much gear reduction. Outrunners are usually the best choice for an ornithopter.

It is important to realize that the amount of power depends more on the windings rather than the size of the motor. A thicker gauge of wire in the coils will draw more current and produce more power. Therefore two identical-looking motors can have completely different performance. You should select a good motor that is intended for model aircraft, rather than trying to use random motors that you take out of some toy.

Tip: Tiny "pager" or coreless motors are great for indoor and micro-sized ornithopters. These inexpensive motors are what makes pagers and cell phones vibrate. They are a special type of brushed motor that has no iron core in the armature.

Whichever motor you choose, the vendor should provide some information on the power output of the motor. How much power do you actually need? For typical ornithopters, you will need about 100 watts per kilogram of flying weight. That should provide the properly designed ornithopter with a good rate of climb.

The battery is just as important as the motor for determining power output. The most common are lithium-polymer batteries. These are in the form of rectangular foil packs, and they produce 3.7 volts per cell. They are the same batteries used in portable electronic devices. Along with voltage, the “discharge rating” of the battery is an important measure of how much power it can produce.

Lithium batteries require a special type of electronic speed controller (ESC) which throttles back the motor when the battery gets too low. Without this, the battery will be ruined if you run it down all the way. Whichever type of battery you choose, it’s important to use the correct charger for your particular type of battery.

Internal combustion engines have been used in ornithopters. Normally, a pull-start engine equipped with a centrifugal clutch and a large heat-sink would be used, similar to what would be found in an RC helicopter or car. Despite the high energy density of the fuels, internal combustion engines are far less efficient than electric motors. Combined with the difficulties of starting, cooling, exhaust, and noise, this weighs against the use of internal combustion engines in most ornithopters. They should be considered for manned ornithopters, or in special applications where the required flight duration cannot be achieved using batteries.

Birds use their body fat to store energy for flight. It contains fifty times more energy, for its weight, than a lithium-polymer battery. That is the main reason why birds can make long distance migration flights, whereas battery-powered ornithopters or model airplanes typically fly for twenty minutes or less.

Ornithopter Gear Design

Whatever type of motor you use, it’s very important to have the right amount of gear reduction linking the motor to the wings. Not enough gear reduction, the motor will overheat. If you have too much gear reduction, the wings won’t move fast enough. For maximum efficiency, you should adjust the gear ratio so the motor is running at about 80% of the speed that it would run with no load. If your mechanism will not allow you to change the gear ratio, you may need to change the size of the wings, or the flapping angle, to get the motor to its optimal speed.

Spur gears are the best choice for ornithopters because of their low friction. You should avoid using worm gears. They might be tempting, because they permit substantial gear reduction in a single stage, but the frictional losses are extremely high! A chain drive might be considered for large or manned ornithopters. By distributing the load onto more of the gear teeth, the chain drive permits weight reduction, and it is nearly as efficient as spur gears.

The limited supply of suitable gears long made it difficult to build electric-powered ornithopters. Recently, the plastic spur gears from Didel have made it much easier to build gearboxes for ornithopter micro-air-vehicles. For larger ornithopters, gears are available from industrial suppliers like Stock Drive Products. It’s often helpful to put a large spur gear on a shaft made of "pinion wire". This provides a simple, lightweight solution for achieving substantial reduction ratios.

There are two ways to build an ornithopter gearbox. The simplest method is to space the gear axles along a linear rail or strut. This method is recommended for micro-sized ornithopters, which usually don't have ball bearings. The other method involves two or more plates with spacers between them. Bearings can be pressed into the plates to hold the gear axles. The plate gearbox design is appropriate for larger RC ornithopters.

Depending on the total reduction ratio you need, your gearbox might have one, two, or three reduction stages. A single stage gearbox is the simplest to build, but it usually won't provide enough gear reduction. Multiple stages add to the complexity of the gearbox but allow you to achieve greater reduction ratios with smaller gears. The gear ratio is simply the product of the individual stages. For example, if the first stage is 5 to 1 and the second stage is 6 to 1, then the total reduction will be 5 x 6 = 30 to 1.

How much reduction is needed? That will depend on your motor selection and what flight characteristics you want the ornithopter to have. If you want small, rapidly-beating wings, or if you have a high-torque outrunner motor, then 30 to 1 might be typical. In other cases, a ratio of 100 to 1 might be better.

Ornithopter Flapping Mechanisms

The purpose of the flapping mechanism is to convert the rotary motion of your motor into the reciprocating motion of flapping wings. There are many ways to do this, and I will describe only some of the more common ones here. The mechanism must be lightweight and fairly simple. Yet it must also provide a fairly symmetric wing motion so the ornithopter flies straight.

The basis for most mechanisms is called a "four-bar linkage". There is a rotating crank shaft, driven by the motor. As the crank goes around, the connecting rods push the wings up and down.

Unfortunately, when a second wing is added, this mechanism will produce asymmetric flapping. The two connecting rods leave the crank at different angles. This causes them to act at different times. The asymmetric flapping lowers the efficiency and makes the ornithopter want to turn to one side. There are several ways to correct this.

Staggered Crank: The simplest solution is to use a staggered crank. Here, the connecting rods go off at different angles, but their timing is corrected by having them placed on separate crank throws. The staggered crank is most easily constructed from bent wire. This limits its use to fairly small ornithopters.

Outboard Wing Hinge: Another way is to separate the wings, so the connecting rods pass together between the wings. Since the angle between the connecting rods is small, the flapping is fairly symmetric. You will need a more complicated body structure to support the outboard wing hinges.

Dual Cranks: Another solution is to use two separate cranks. This requires an additional drive shaft and gear. This mechanism will probably weigh a little more, but the flapping will be almost perfectly symmetric.

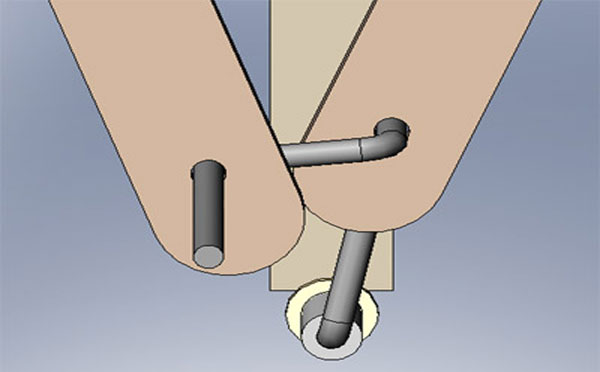

Transverse Shaft: A variation on the dual crank idea is to use a single drive shaft, mounted crossways in the ornithopter, with cranks at either end. Since the cranks are not operating in the same plane as the flapping arc, the connecting rods must have ball joints at their ends. This results in more friction compared with ball bearings operating in a single plane.

In addition to these basic designs, many other mechanisms have been developed for special purposes, such as flapping multiple wings, moving the tail along with the flapping motion, or actively twisting the wing structure as it goes through the flapping cycle.

Ornithopter Wing Design

As with the flapping mechanism, there are many ways to build an ornithopter wing. The simple "membrane" type of ornithopter wing is the most commonly used. This is not only because it is easy to build. It is also the most consistently successful ornithopter wing design.

The membrane wing consists of a spar, at the leading edge of the wing, and a wing membrane, which extends backward from the spar and attaches to the body of the ornithopter. Notice that the rigid structure is concentrated at the front of the wing. The same is true for birds, bats, pterosaurs, and most insects. When flapping, the more flexible membrane portion of the wing will passively lag behind the rigid wing spar. We refer to this as "twisting" of the wings. It is important, because it keeps the wing adjusted to the correct angle for both the upstroke and the downstroke.

The angle between the wing surface and its direction through the air is called the "angle of attack". People often wonder why the upstroke of the bird's wing doesn't push the bird back down. It's because the angle of attack is adjusted, so that the wing can pass easily through the air. In the downstroke, the angle of attack is higher, so the wing produces more force. The force perpendicular to the wing surface is called "lift".

Sometimes it is possible to improve the basic membrane wing, by adding a diagonal brace to the wing structure. The left picture shows one of the "Seagull" engine-powered ornithopters, developed by Percival Spencer in the 1950s. He built a whole series of these models, up to eight foot wingspan. The brace holds some tension on the wing membrane and prevents it from having too much twist. The brace must be flexible so the wing can take on a curved airfoil shape while under load.

After Spencer it became a common practice to add some battens in addition to the Spencer wing brace. The battens cross over the diagonal brace, and their purpose is to extend the outline of the wing membrane. The battens should radiate outward from the front, inside corner of the wing. In this way, they do not interfere with the natural cambered shape of the wing. The photo shows the Spencer wing brace in red and the additional battens in green.

Various materials may be used for the construction of membrane wings. Traditional rubber-band-powered ornithopters are made from balsa wood, with either a lightweight tissue paper, or a plastic film forming the wing membrane. Radio controlled ornithopters mostly use carbon fiber rods for the wing spars. The wing membrane can be made from a plastic film. This is suitable, even for fairly large RC ornithopters. Look for a crisp, non-stretchy type of plastic film, instead of the sandwich-wrap type. Sometimes a woven fabric is used. The fabric wings can look very professional. However, it will be difficult to find a woven material that is crisp, lightweight, and airtight. Some of the fabrics specially made for kites may be appropriate.

Ornithopter Stability and Control

Getting an ornithopter to fly is only half the battle. It can also be very difficult to make an ornithopter steer correctly. In all fairness, though, we create this problem ourselves by not putting a vertical fin on the ornithopter. Airplanes always have a vertical fin, because it helps them fly straight. Ornithopters ususually don’t have one, because we want it to look more like a real bird. The price for that is reduced stability. If we insist on using a flat, triangular tail, like a bird, that will increase the challenges of stability and control.

In ornithopters, the tail is usually angled up quite a bit, which is different from airplanes or birds. This is because the ornithopters are built “nose-heavy” and need the tail like this to prevent a nosedive. Not all ornithopters are like this, though. In certain rubber-powered ornithopters, the motor stick has been elongated in an effort to increase duration. With the center of gravity or balance point farther to the rear, the stabilizer lies flat like an airplane tail and provides lift instead of downforce. Obviously, the lifting stabilizer is more efficient. However, the more rearward location of the balance point can decrease the directional stability of the ornithopter. Then your ornithopter will definitely need that vertical fin, which we were trying to get away from in the first place.

Slight differences between the two wings can cause the ornithopter to turn left or right. If the wing spars are made of wood, their weights will naturally differ. You can also have asymmetry in the mechanical properties of carbon rods, or in the tension of the wing membrane. If the ornithopter wants to turn to one side, this can be corrected by adding weight to the wingtip on the outside of the turn. Through inertia, the added weight acts to suppress the flapping motion of the weighted wing, while increasing the flapping amplitude of the unweighted wing. The difference in travel results in a difference in thrust that will compensate for any unexplained pull to one side.

Steering is usually done by the tail. In one method, the tail swings out to the side, so the downforce of the tail causes a rolling force on the ornithopter. Alternatively, the tail will rotate about its long axis. In this case, the downforce is redirected in a way that provides yaw control, like a rudder. In some RC ornithopters, the tail rotates about an oblique axis, combining the two motions described here. The wings can be used for steering, but this is less consistently successful and more difficult to implement.

Be sure to check out the Ornithopter Design Manual for more information about how to build ornithopters.